Air diaphargm pumps are used to paint paint, also known as paint film pumps, which are widely used in paint industry or in electronic paint spraying industries.

The Air diphargm pump used to paint paints is very diverse in design, style, capacity and origin so it is difficult for users to know which is the best, most affordable paint film pump. .

Cheap diaphragm paint pump

Air diaphargm pump used to paint any kind of good?

To evaluate the quality of paint film pumps is not easy, because each type of diaphragm pump has different advantages and disadvantages when using, the advantage of this type of machine is sometimes the disadvantage of this type of machine. that. Especially, each type of diaphragm pump is manufactured and supplied to the market aiming at different users, so it is necessary to assess the quality of each user on the demand and use. diaphragm pumps, from which to choose the type of diaphragm pumps used most effectively.

Customers can also refer to the type of pneumatic pumps used for paint pump used in businesses today in Vietnam such as: Marathon, Aro, Jofee, Blagdon, Husky, Sandpiper paint pumps of the US , Yamada of Japan, TDS of Taiwan … These are paint film pumps with an affordable price, good warranty, long life, easy-to-find and best-selling replacement parts on the Vietnamese market. and the world today.

Suction throat discharge size of Air diaphragm pump

The diaphragm pump has many sizes of suction and discharge throat to suit each customer’s needs.

– Diaphragm pump 1/4 inch

– Diaphragm pump 1/2 inch

– Diaphragm pump 1 inch

– Diaphragm pump 1.5 inch

– Diaphragm pump 2 inch

– Diaphragm pump 3 inch

Instruction for choosing paint film pumps

To choose the type of paint film pump or pneumatic pump used to paint best, best suited to your needs, the user can refer to the following experience:

– Determine the liquid to be pumped: Solid or liquid paint, whether it is doped or not

– Determining the capacity to pump

– Determination of pump flow

– Determining the cost of using diaphragm pumps

– Learn carefully the structure, operation mode, advantages and disadvantages of the pneumatic pumps used for paint pumps, especially the paint film pumps that are in demand or have been planned to buy.

– Please select the diaphragm material suitable for the type of paint you need to pump

– Pay attention to the air valve assembly as this is the part that determines the performance of the diaphragm pump.

Because paint is a common pump, it is not too corrosive and abrasive, so when choosing a diaphragm pump you can choose the pump body made of plastic, cast iron or stainless steel or even aluminum. About diaphragm pumps you can also choose any type of diaphragm to suit your budget.

Pneumatic pump for painting

How do Air diaphargm pumps for paint pumps work?

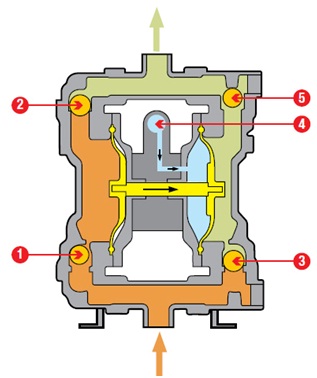

Like other conventional air diaphragm pumps, the paint diaphragm pump operates on the principle of using compressed air to push the diaphragm pump to push fluid away.

Refer to the operation diagram of the diaphragm pump:

Working principle of paint film pump

Advantages of paint film pumps

In addition to common advantages like other diaphragm pumps, pneumatic pumps for paint pumps have additional outstanding advantages, which is why most businesses use paint film pumps for their work.

– Various materials for manufacturing pumps

– High quality paint pump, durable, easy to use

– Components are affordable, easy to find, easy to replace

– Can be used for all types of paints, including solid and mixed paints

– No mechanical seals or other sealing parts are needed to prevent leakage.

– No need to bait yourself

– Varied pump pressure and pump flow

– Even running dry will not worry about heat generation and damage to the machine

– No need to use pressure reducing valve

– Save time and money by not using mechanical seals

As such, paint film pumps are the perfect choice for paint manufacturers or industries that need paint pumps.