Besides conventional pumps, high pressure pumps, have you ever heard of metering pumps? This can be considered as a quite special pump and is applied a lot in manufacturing in many different fields.

What is a metering pump?

Diaphragm metering pump

Dosing pump is a type of pump with a small volume of flow. The pump is designed to pump chemicals, or any liquid, into the water at a precise rate by means of an automatic pump or can be operated manually in some cases.

Dosing pumps are often used to pump fluids, highly corrosive materials such as acids or alkalis, viscous substances, high viscosity, high temperature substances …

Dosing pumps have a rather small design, they operate by an electric motor or air transmission and are controlled by an external control system such as flow rate change control, on / off function, warnings during operation …

Dosing pumps are not only used in wastewater treatment technology, they are also used in agriculture, industry, medicine …

General structure of the metering pump

On the market today, metering pumps are divided into 4 main types:

– Piston type metering pumps

– Hydraulic metering pump

– Diaphragm metering pumps

– Electronic metering pumps

Each type of pump has different mechanisms, ways of operating, different structural design, but the metering pump structure has some things in common:

1. Chemical containers

2. Check valve: Usually placed in the suction and ejector of the pump

3. Pump body / pump chamber: Depending on many factors: manufacturer, pump type, etc., they may vary in size and manufacturing materials. But in general, the pump body / pump chamber is usually made of resins that are resistant to corrosion by chemicals such as PVC, PE., Rubber or stainless steel. The pump body is fitted with:

o Suction head

o Dosing pipes

o Pushing head

o Some other parts depend on each type of pump such as: piston, diaphragm pump, flow sensor unit …

4. Conductor: usually PVC or PE pipes, if pumping high temperature chemicals or pumping with high pressure, the conductor can be made of stainless steel

5. Sprayer: push chemicals out. There is a one-way valve design that allows chemicals to come out. At the nozzle, there can be additional nozzles to put chemicals in to keep the flow to avoid pipe corrosion if sprayed just outside the edge of the pipe.

6. Control system: Purpose to ensure accurate quantification, can turn on / off at specific time. It can be the system of automatic center vibration control or manual control

Principle of operation of the metering pump

Dosing pumps operate on a simple principle that consists of 4 processes:

1. Chemical self-priming process

This is the first process to be done. In this process the chemicals are pushed into the priming chamber until filled, and can be replenished during pump operation.

2. Suction process

When the engine is running, chemical suction is done. Open check valve, chemicals are sucked into the pump chamber. After chemical fills the pump chamber, the check valve automatically closes.

3. Push process

As soon as the one-way valve in the suction line closes, the chemicals reach the outlet, the check valve opens, the chemicals are pushed out.

4. Process of adjusting the pump flow

The adjustment of the pump flow can be done manually or automatically depending on the different pump types

Dosing pump used to do?

Dosing pumps are widely used in many different manufacturing industries, from water treatment, agriculture, industry, manufacturing, processing, open mining and even in health.

Pumps are designed to inject an exact amount of product (usually chemical) into a stream of water or liquid to perform a chemical or physical reaction. For example, adding chlorine to water to kill bacteria, adding acids and solutions to adjust pH, or used to precipitate solids contained in liquids, creating favorable conditions to remove them … This helps stabilize the production, stabilize the product quality.

Different types of metering pumps will be used in different fields.

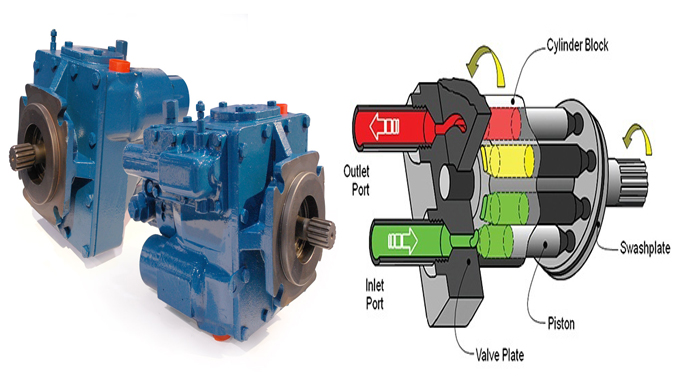

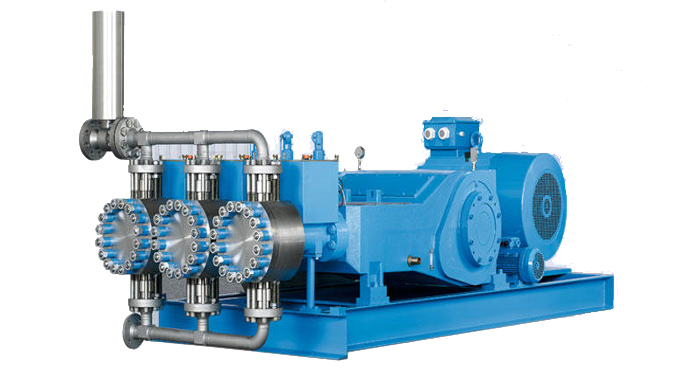

1. Piston dosing pump

This can be considered the most classical pump, the most powerful. In practice, piston pumps are often used when:

– The system requires high pressure

– The material to be pumped is not an abrasive substance or a solid-containing compound so that it does not abrade or destroy the piston gasket

– Anti-leakage requirement is not too strict

2. Hydraulic metering pump

Choose this type of pump in cases such as:

– The system requires high pressure

– Substances to pump are abrasive compounds, containing suspended solid residues, which are toxic

– There is a high demand for anti leakage or air leakage

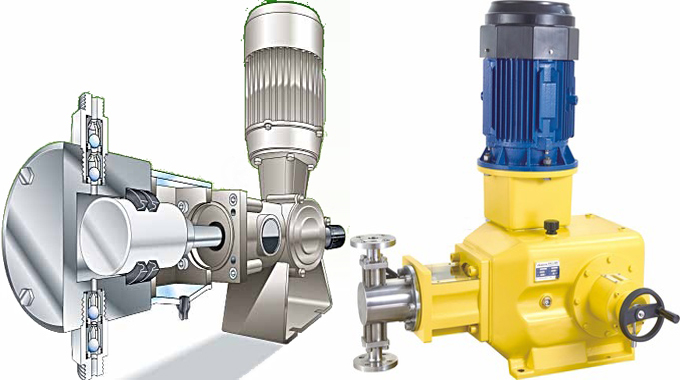

3. Diaphragm metering pump

Membrane metering pumps are often used when it is necessary to determine the exact amount of liquid to be supplied, so they are often used in laboratories, in chemical manufacturing, in medical applications. In addition, they are also used to pump liquid, slurry or sewage, used in a number of oil industries, chemical industries, marine, paper production …

4.Several other types of metering pumps

These include: manual dosing pumps, electronic dosing pumps, automatic control, etc. These pumps are used for: treatment of inorganic sludge, industrial chemical sludge, sludge for real technology industry. Products…